! “Made in Japan”... Japan manufactures the thinnest surgical needles in the world

As the world's surgical needle manufacturing technology advances, a small manufacturer has revolutionized the field of regenerative surgery and other medical applications. Headquartered in a suburb east of Tokyo, the “Crown John” needles produced by Kono Seisakusho have improved surgical procedures and opened the horizon for their use in advanced fields of medicine. These needles are used throughout Japan, bringing international attention to the company's achievements and developments in surgery and healthcare.

Thin enough to suture blood vessels

The diameter of the thinnest surgical needles in the world is 0.03 millimeters, and their length is only 0.8 millimeters. Also, the thread that this needle pulls is so thin, at 0.012 mm in diameter, that it is not visible to the naked eye. The development of “Crown John” needles by Kono Seisakusho Company, a small Japanese company specializing in the manufacture of precision devices, may have revolutionized several areas in the field of medicine and surgery, especially in regenerative surgery, as it became possible to sew blood vessels, lymphatic vessels, and nerves that Its thickness is less than 0.5 mm, which was previously considered impossible. These needles have proven effective in other areas of surgery as well, such as reattaching an infant's severed finger.

Microsurgical needles compared to a sesame seed. Photo: Courtesy of Kono Seisakusho

Needles with a diameter of 0.1 mm, which were used in microsurgery (operations performed using microscopes), were the standard in the past. It was difficult to perform sutures or any other procedure on tissues smaller than 0.5 mm using those large needles. But now, thanks to the availability of 0.03mm needles, skilled surgeons can perform surgeries that require “ultra-microscopic” procedures, such as ligating blood vessels that are only 0.1mm thick.

Overcome multiple obstacles

The development of 0.03 mm diameter needles was completed in 2004 after three years of work. “At that time, people in the medical field generally agreed that there was no need for medical needles with such a thin, thin and precise diameter, and that none of the manufacturers had the technology to produce them,” recalls Kono Jun'ichi, president of Kono Seisakusho. However, a doctor at a university hospital asked Kono about the possibility of manufacturing thinner diameter needles, which prompted Kono to begin working toward the 0.03 mm diameter goal.

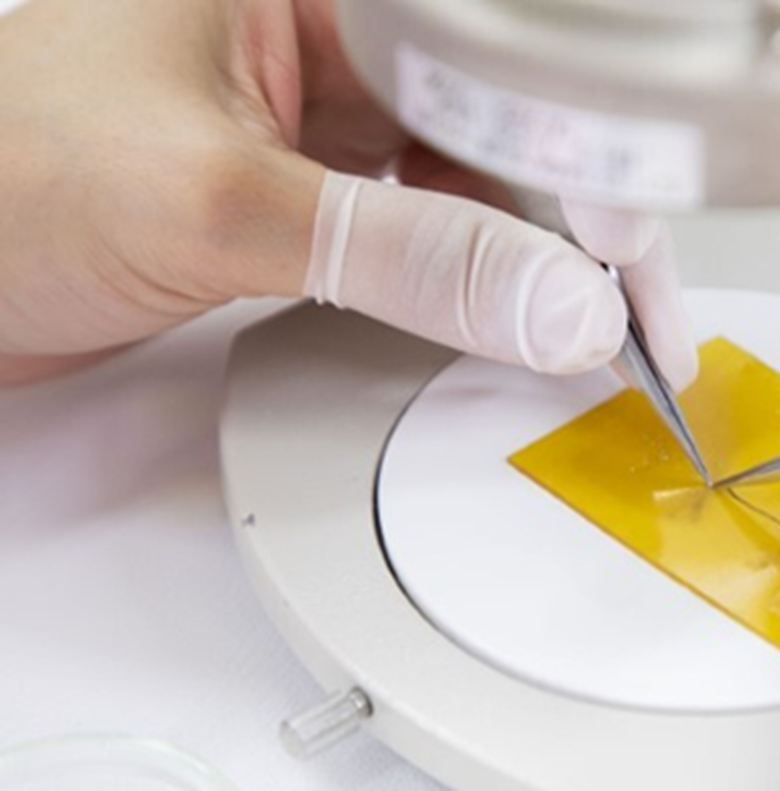

It turned out to be extremely difficult to implement. Surgical needles are made from a special type of stainless steel that is stretched and cut, then one end of the needle is thinned to a certain degree, then bent and its point is sharpened. But with such a small diameter, the metal material becomes soft, similar to cotton fibres, so each needle must be produced individually by a skilled artist using a microscope. Kono Seisakusho has developed its tools and mechanisms specifically for this purpose.

Kono Jun'ichi - President of the Kono Seisakusho Company

Another hurdle is finding a way to enable the suture thread to be inserted into the very thin needle. In the case of regular surgical needles, a hole is opened to insert the thread at one end using a drill or laser beam. But because there was no drill thin enough to open a hole in a 0.03 mm diameter needle, and because the temperature of the laser radiation could melt the metal, Kono devised a method based on a traditional technique: it split the base of the needle into two halves, each with a tapering protrusion. at the end, then she pressed the thread between them.

An imperial visit to a small company

Kono Seisakusho was founded in 1949 as a manufacturer of parts such as needles used in measuring instruments. In the mid-sixties, the company shifted its activity to the field of medical devices, and since then the company has developed and produced surgical needles with threads of various specifications. It attracted attention in particular due to its leadership in the development of microneedles, and was recognized by the Small and Medium Enterprises Agency of the Ministry of Economy, Trade and Industry in 2008 as one of the top 300 manufacturing projects in Japan and won the Prime Minister's Award, the highest honor in the Monozikuri Nippon Grand Awards. (Promoting Excellence in Commodity Production) in 2009. The following year, Emperor Akihito visited the company's headquarters factory.

It is worth saying that the size of the local market for surgical needles in Japan is 25 billion yen annually. There are approximately ten Japanese and foreign companies active in this field. Kono Seisakusho currently produces about 10,000 types of needles, which it supplies to public hospitals across the country. As President Kono explains, his company's unique strength lies in its ability to produce many different goods in small quantities, something larger companies cannot do. He states that the company handles everything from marketing to planning, design, development and production in-house, adding that the company also builds most of its own manufacturing equipment.

Surgical needles account for about 80% of Kono Seisakusho's sales. Ultra-fine needles and other handcrafted items are produced at the factory at the company's headquarters in Ichikawa, Chiba Prefecture, while mass-produced items are manufactured at the Tsukuba factory located in Gusu, Ibaraki Prefecture. As for the headquarters factory in Ichikau, production requires extreme precision in work, which requires great concentration, as more than half of the employees are women, and many of them also commute to the workplace by bicycle after leaving their children in nurseries or kindergartens. They work in a very quiet environment, very different from the factory floor.

International sales development

Since needles with fine diameters greater than 0.05 mm are classified as specialty products, the scope of domestic sales remains limited. However, due to advances in transplantation techniques and increased use of regenerative medicine, the demand for these needles is expected to increase. At the same time, the microsurgery healthcare market is expanding with the advancement of medical treatment, both in developed countries and in emerging countries in Asia. Therefore, Kono Seisakusho is expanding its sales channels both domestically and internationally.

Kono Jun'ichi - President of the Kono Seisakusho Company

The company is already hosting a stream of visitors from Thailand, Vietnam, China and other Asian countries - where the market is expected to grow. The company established an office in China in 2012 and is seeking to expand globally. The company warmly receives all ideas for new products from hospitals, whether inside or outside Japan, and is also studying the possibility of conducting product development activities in China. President Kono is enthusiastic about his company's unique technologies and is fully confident in the capabilities of Crown John's surgical needles.

Source: websites